Advancing Products Through Mechatronics Engineering

Mechatronics engineering, also called mechatronics, is an interdisciplinary branch of engineering that focuses on the integration of mechanical engineering, electrical engineering, electronic engineering and software engineering, and also includes a combination of robotics, computer science, telecommunications, systems, control, automation and product engineering.

-Austin- mechatronics

Research + Development

Research and development (R&D) is a systematic process focused on the innovation, design, and improvement of products and technologies. It involves investigating new concepts, testing prototypes, and refining solutions to meet market needs or enhance existing offerings. In engineering and manufacturing sectors, R&D plays a crucial role in advancing technical capabilities, ensuring competitiveness, and driving growth through the practical application of scientific knowledge. Effective R&D requires collaboration across multiple disciplines and rigorous evaluation to deliver reliable, efficient, and scalable outcomes.

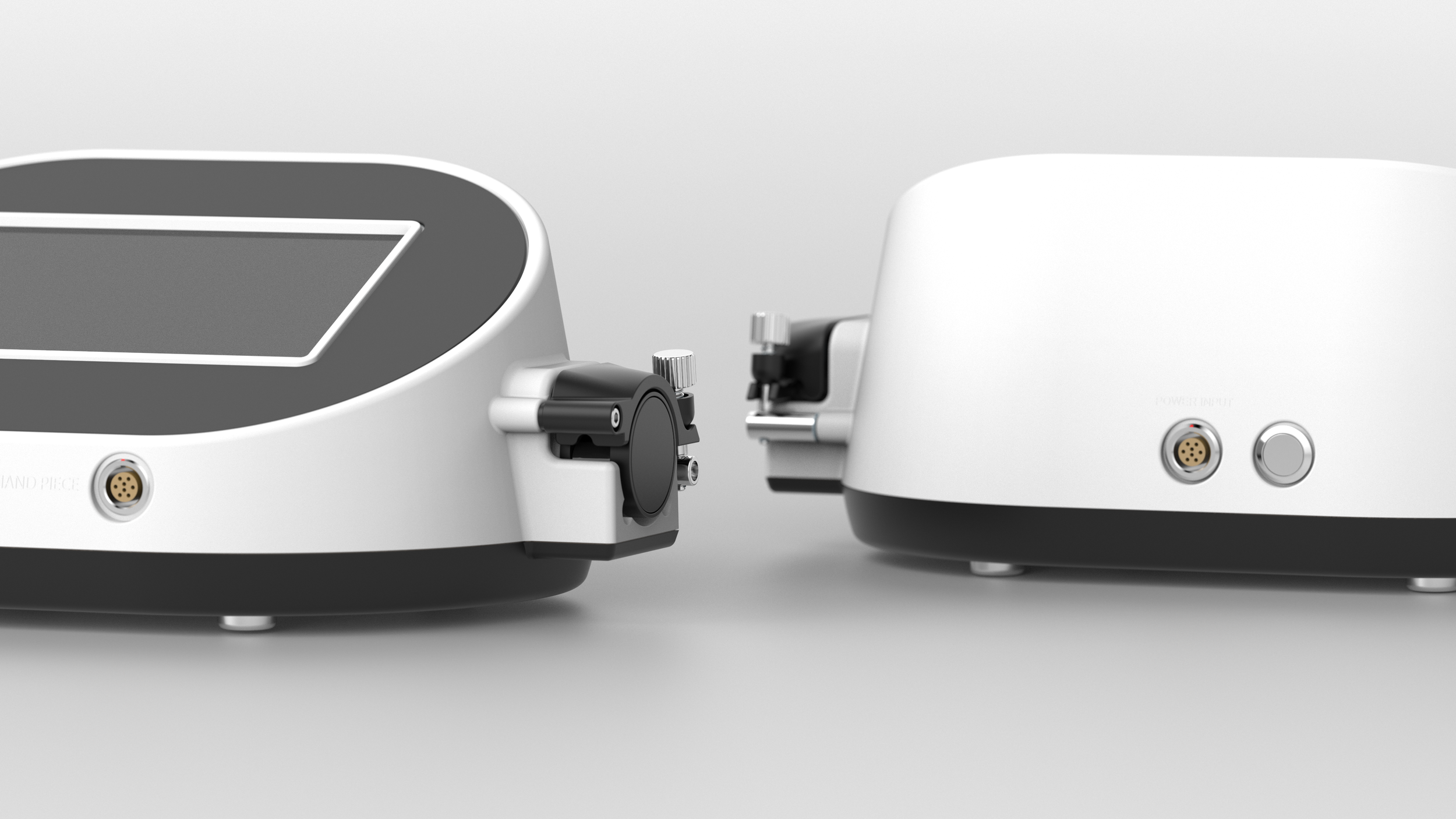

mechatronics engineering

Mechatronics engineering is an interdisciplinary field that combines mechanical engineering, electronics, computer science, and control engineering to design and develop intelligent systems and products. It focuses on integrating mechanical components with sensors, actuators, and microcontrollers to create automated and efficient machines. This field plays a critical role in modern industries such as robotics, automotive, aerospace, and manufacturing by enabling advanced functionality, precision, and adaptability. Mechatronics engineers work on everything from hardware design to software programming, ensuring seamless interaction between physical devices and digital controls.

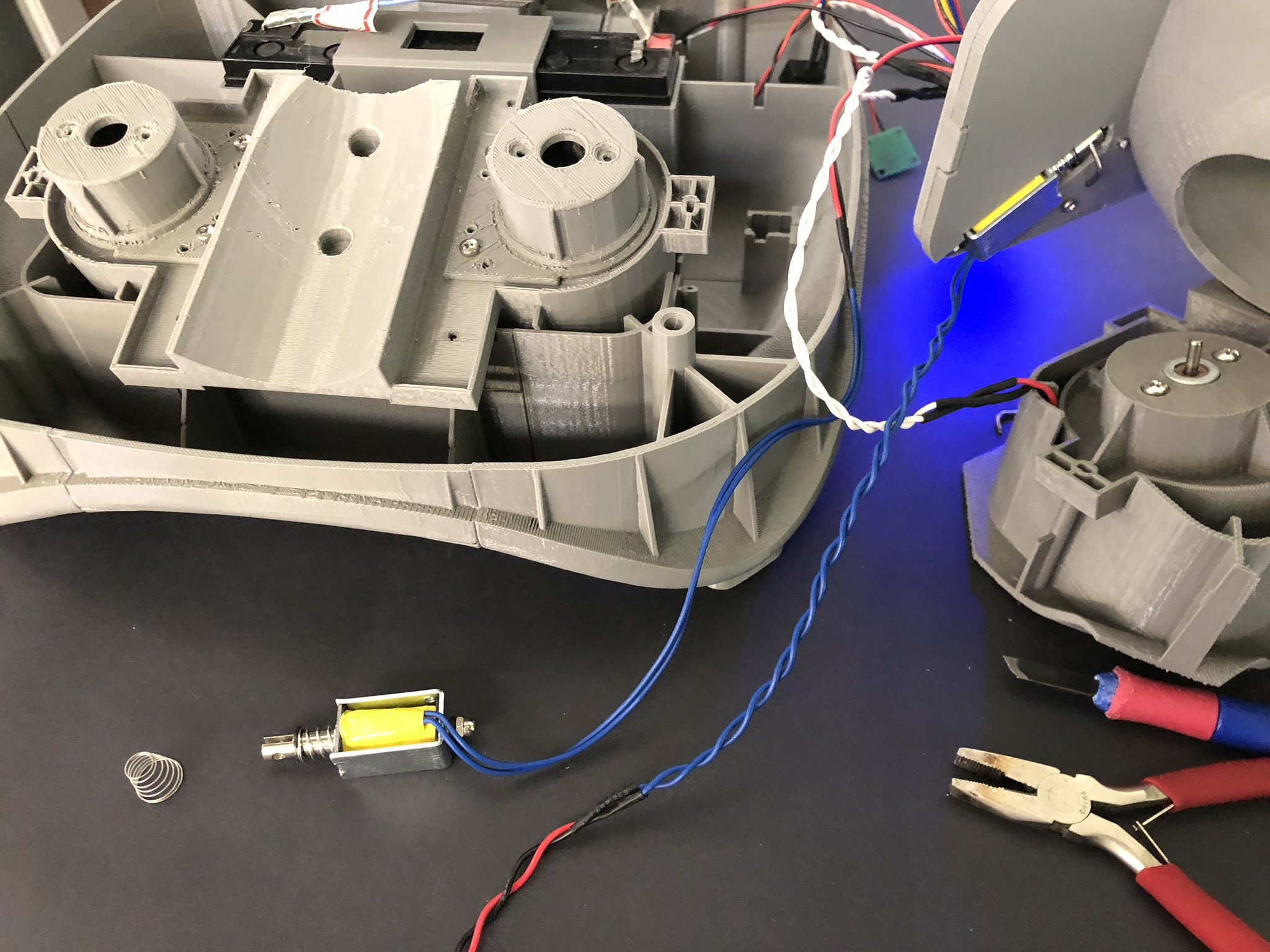

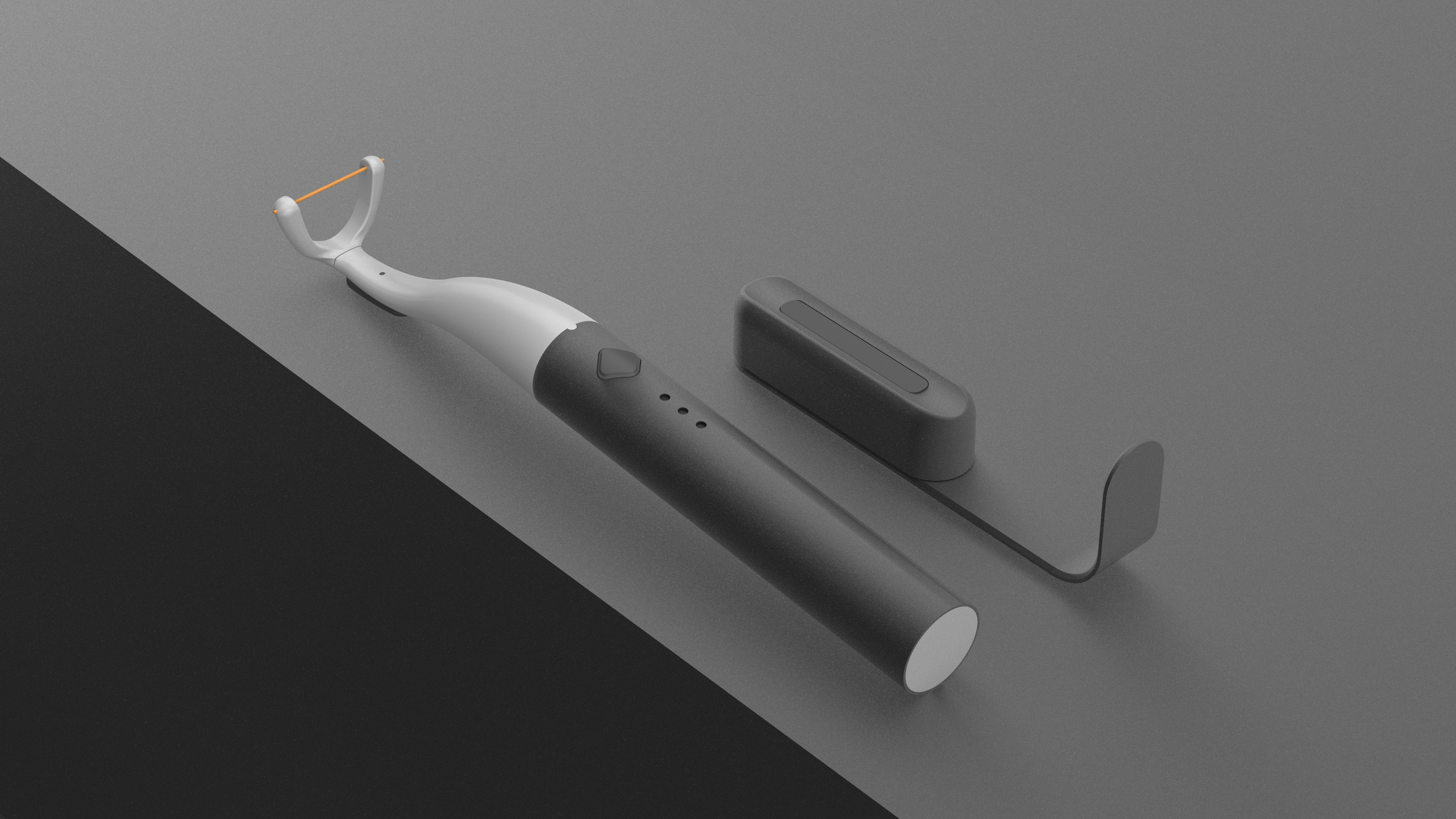

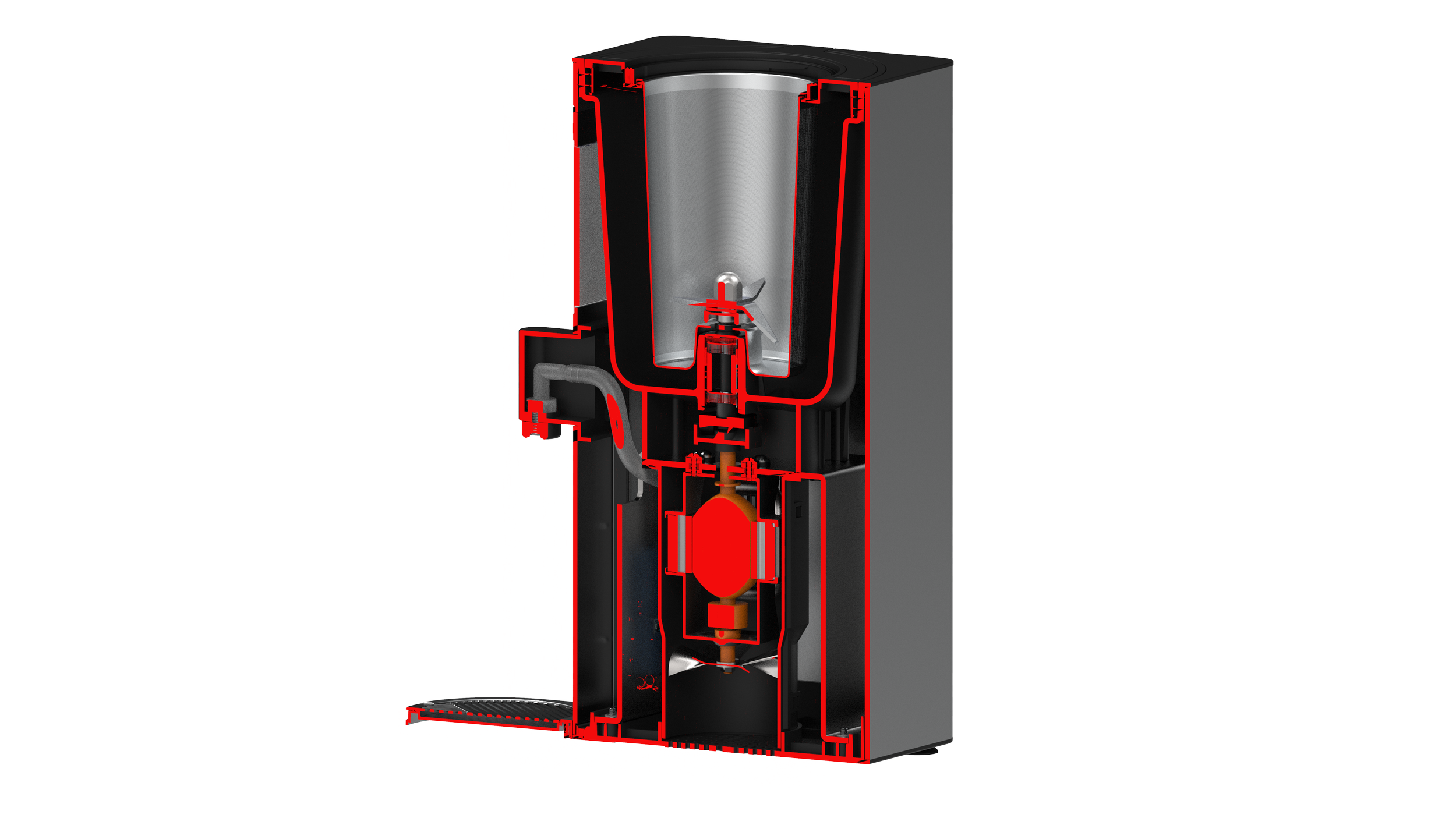

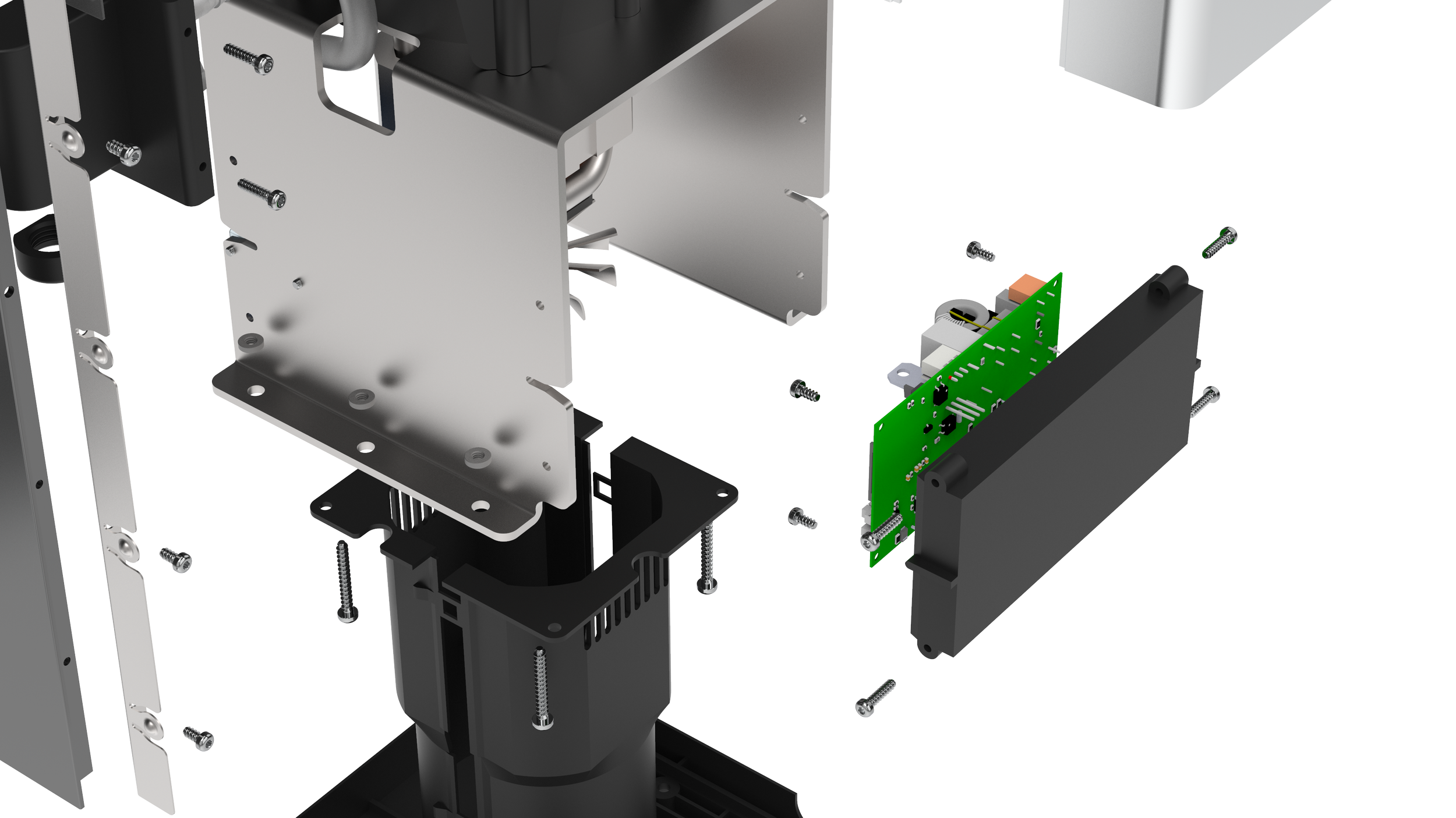

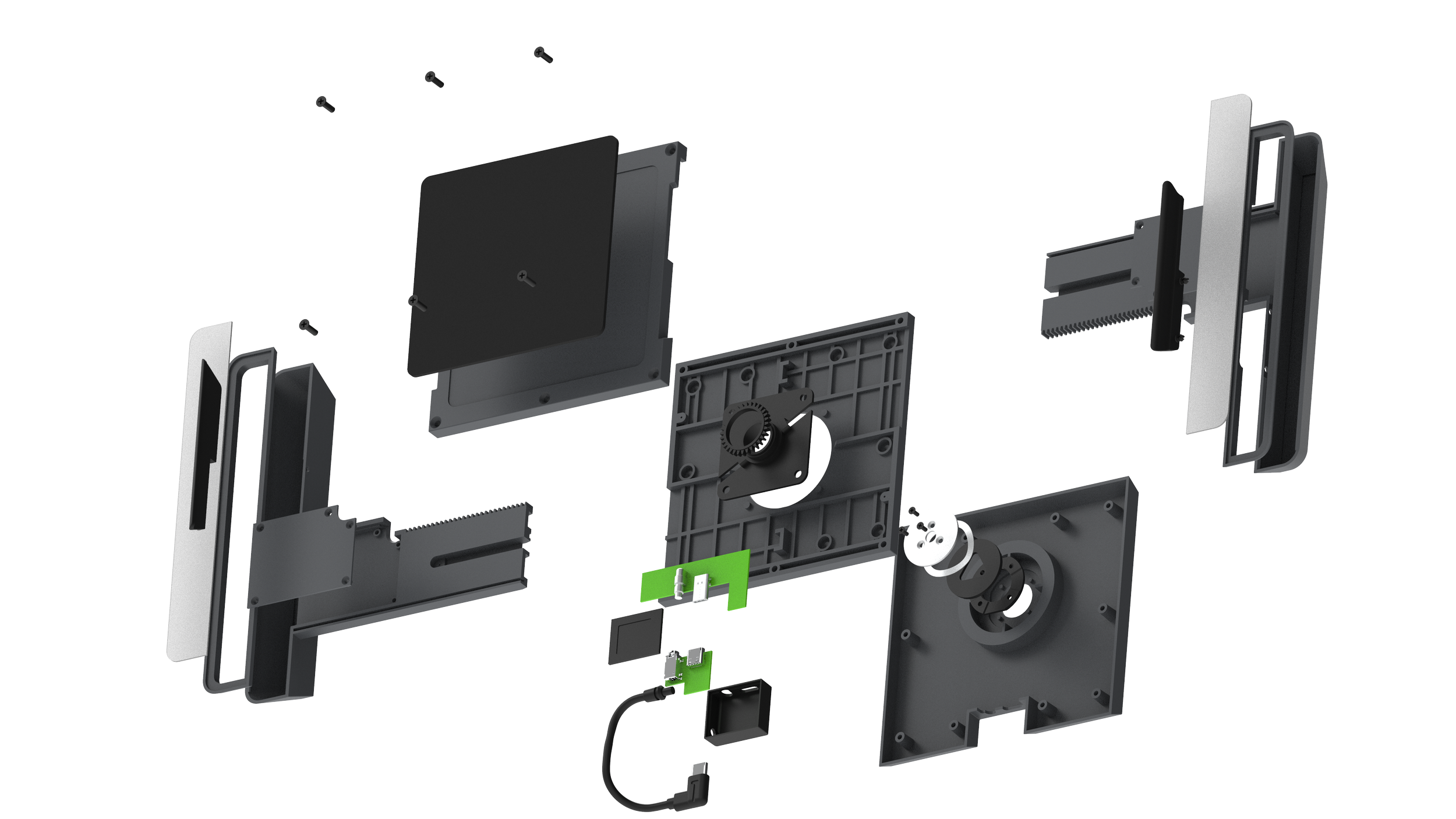

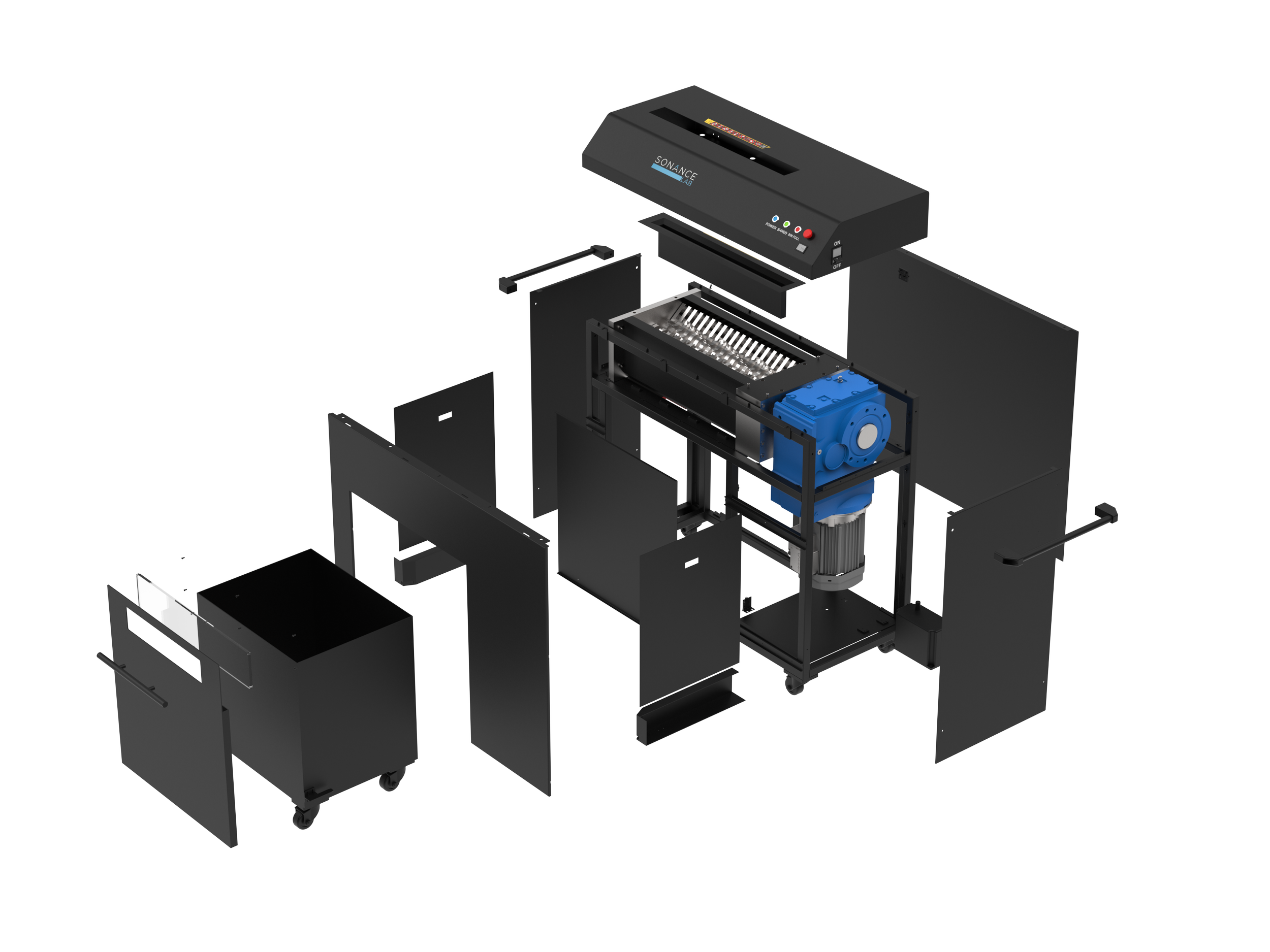

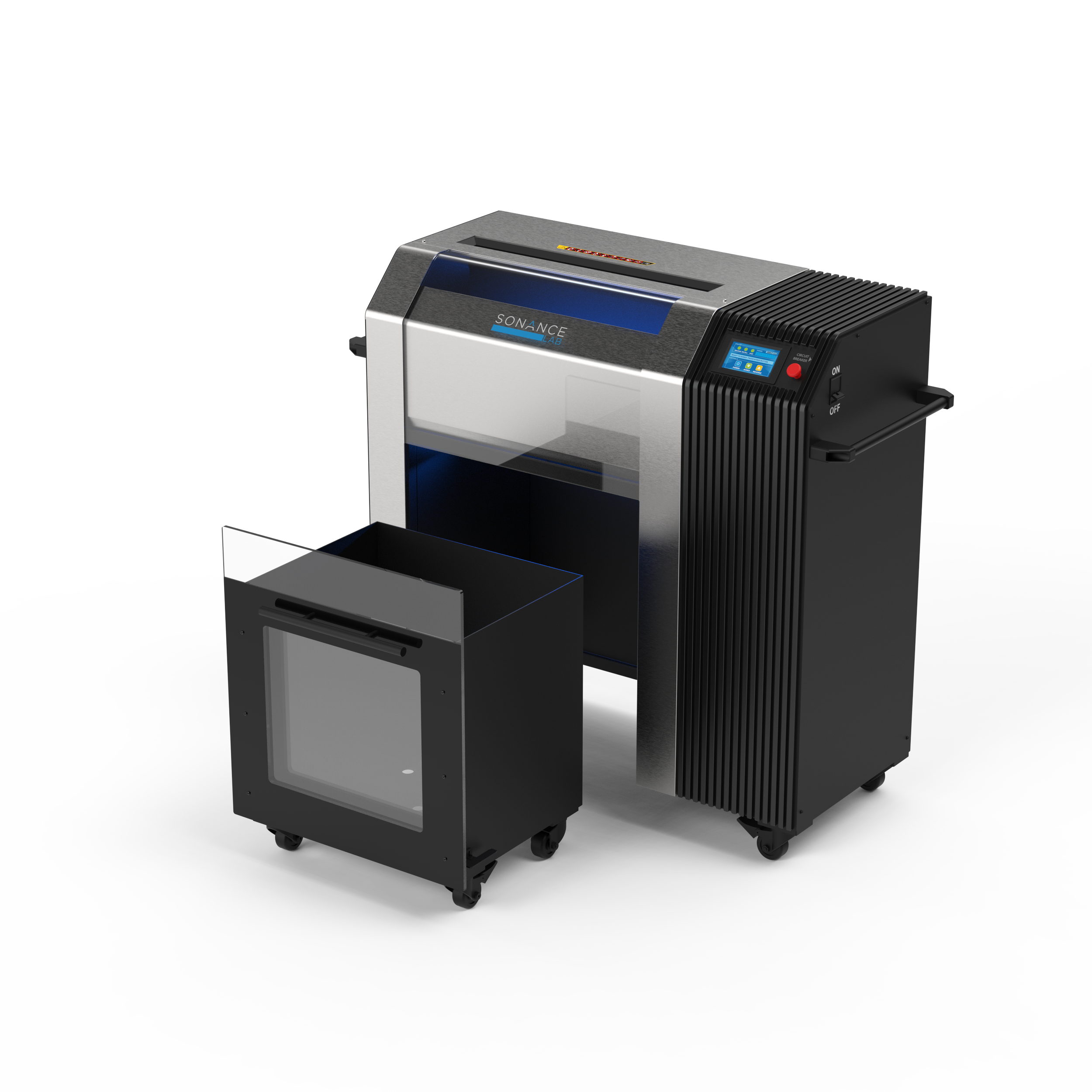

Physical prototypes

Prototyping is a critical phase in hardware design that involves creating a preliminary model of a product to evaluate its functionality, design, and usability. It allows engineers to identify potential issues early in the development process, test new concepts, and gather feedback before committing to full-scale production. By using iterative prototyping techniques, teams can refine mechanical and electrical components, optimize performance, and ensure that the final product meets both technical specifications and user requirements. This approach minimizes risks, reduces development costs, and accelerates time to market.

Get in touch.

It all begins with an idea. Maybe you want to launch a business. Maybe you want to turn a hobby into something more. Or maybe you have a creative project to share with the world. Whatever it is, we are her to help.

details

-

Andrew Namminga

Chief Technologist

A knowledgeable leader like Andrew Namminga is important because he brings expertise and insight that drive informed decision-making and strategic innovation. His deep understanding of both technical and operational aspects enables the team to navigate complex challenges efficiently, fostering a culture of continuous improvement. By combining experience with clear communication, he ensures alignment across all levels of an organization, ultimately enhancing productivity and the successful execution of projects. Such leadership is crucial in dynamic fields like hardware design, where precision and adaptability are essential for staying competitive.

-

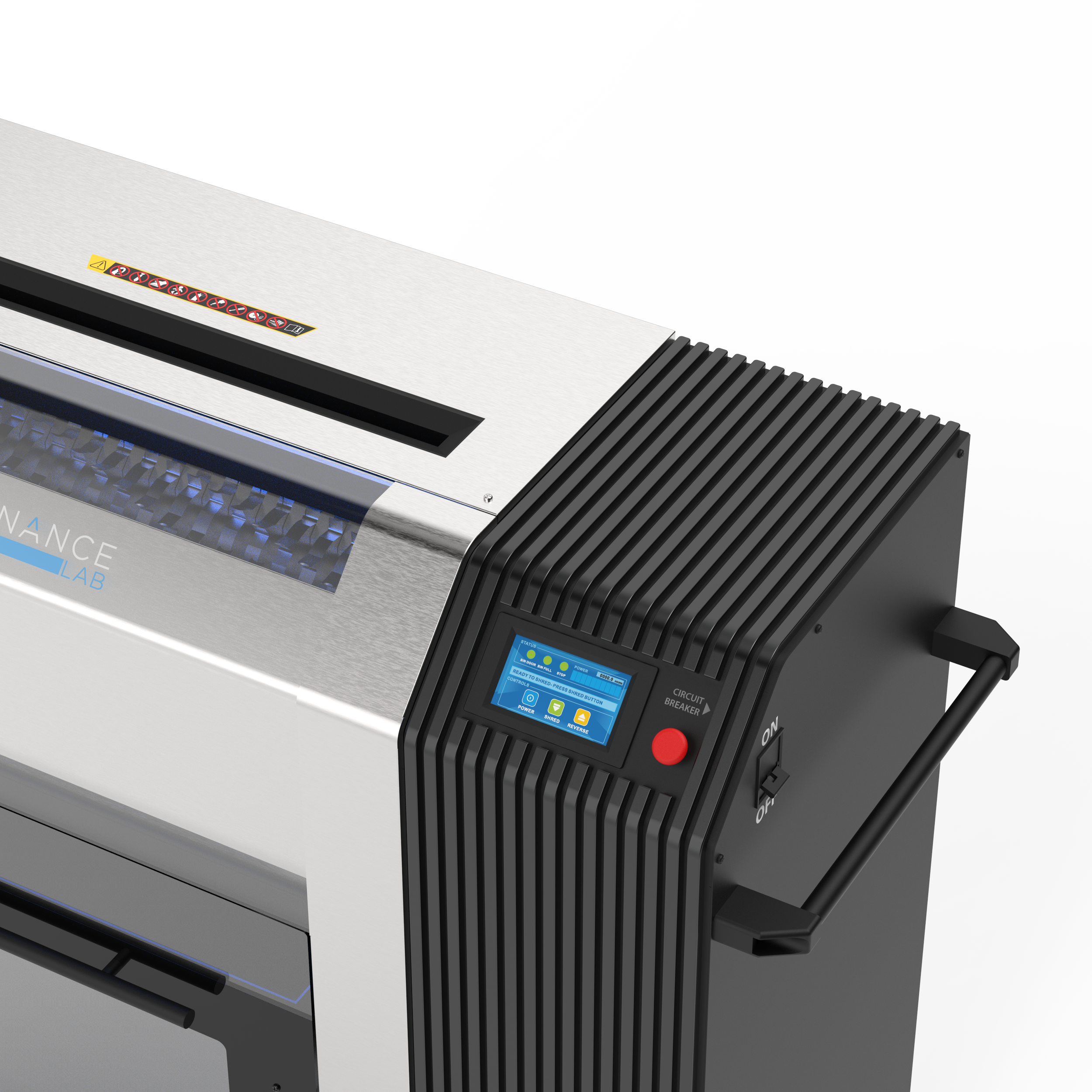

ATX laboratory

Mechatronics in Austin Texas

The hands-on prototype facility in Austin, Texas, offers comprehensive resources for rapid development and testing of hardware designs. Equipped with state-of-the-art tools, including CNC machines, 3D printers, electronics workbenches, and assembly stations, the facility supports every stage of the prototyping process. Engineers and designers benefit from direct access to fabrication equipment, allowing for quick iteration and refinement of mechanical and electronic components. This facility enables streamlined project workflows, reducing the time from concept to functional prototype while maintaining high precision and quality standards essential for successful product development.

-

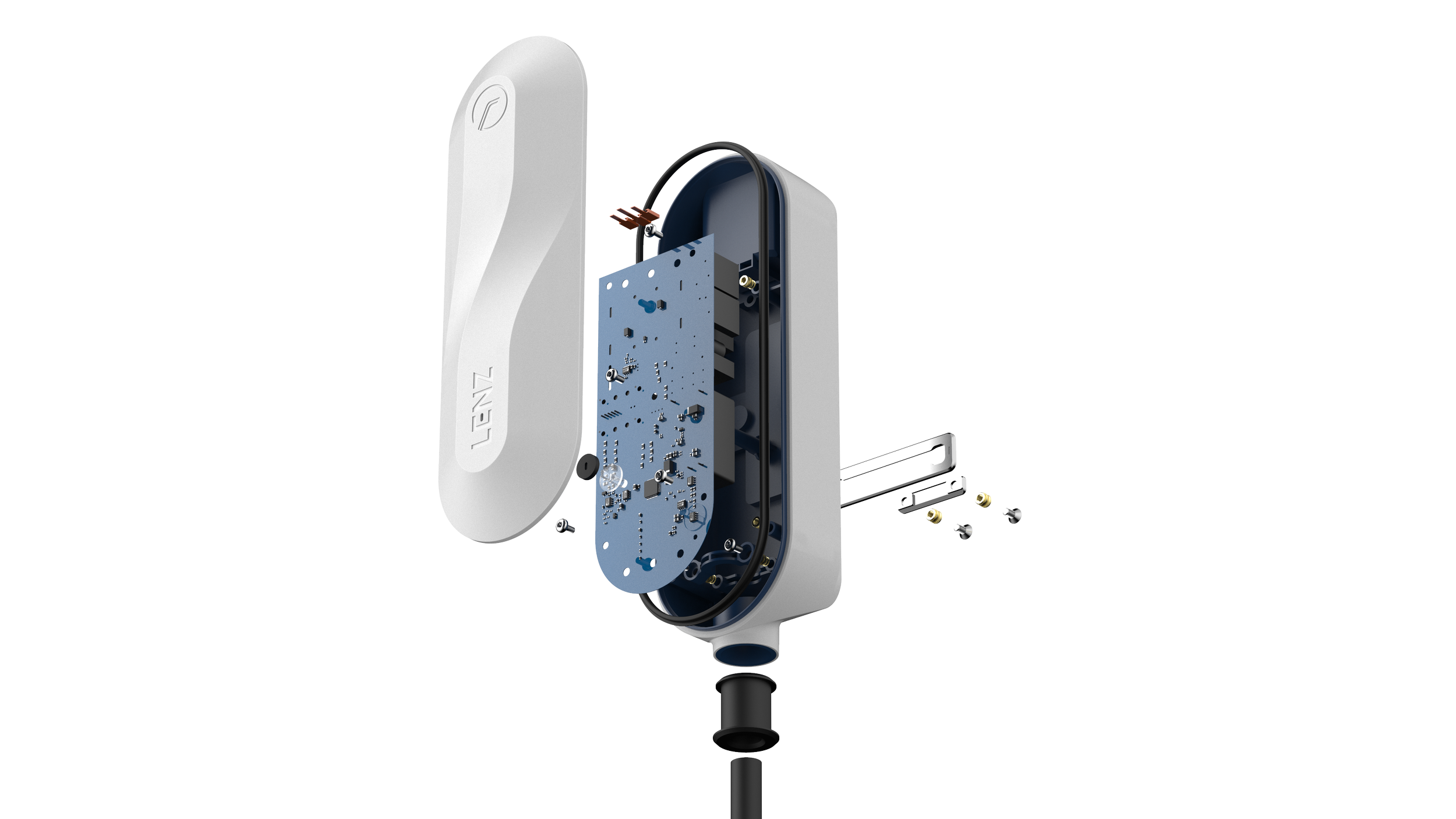

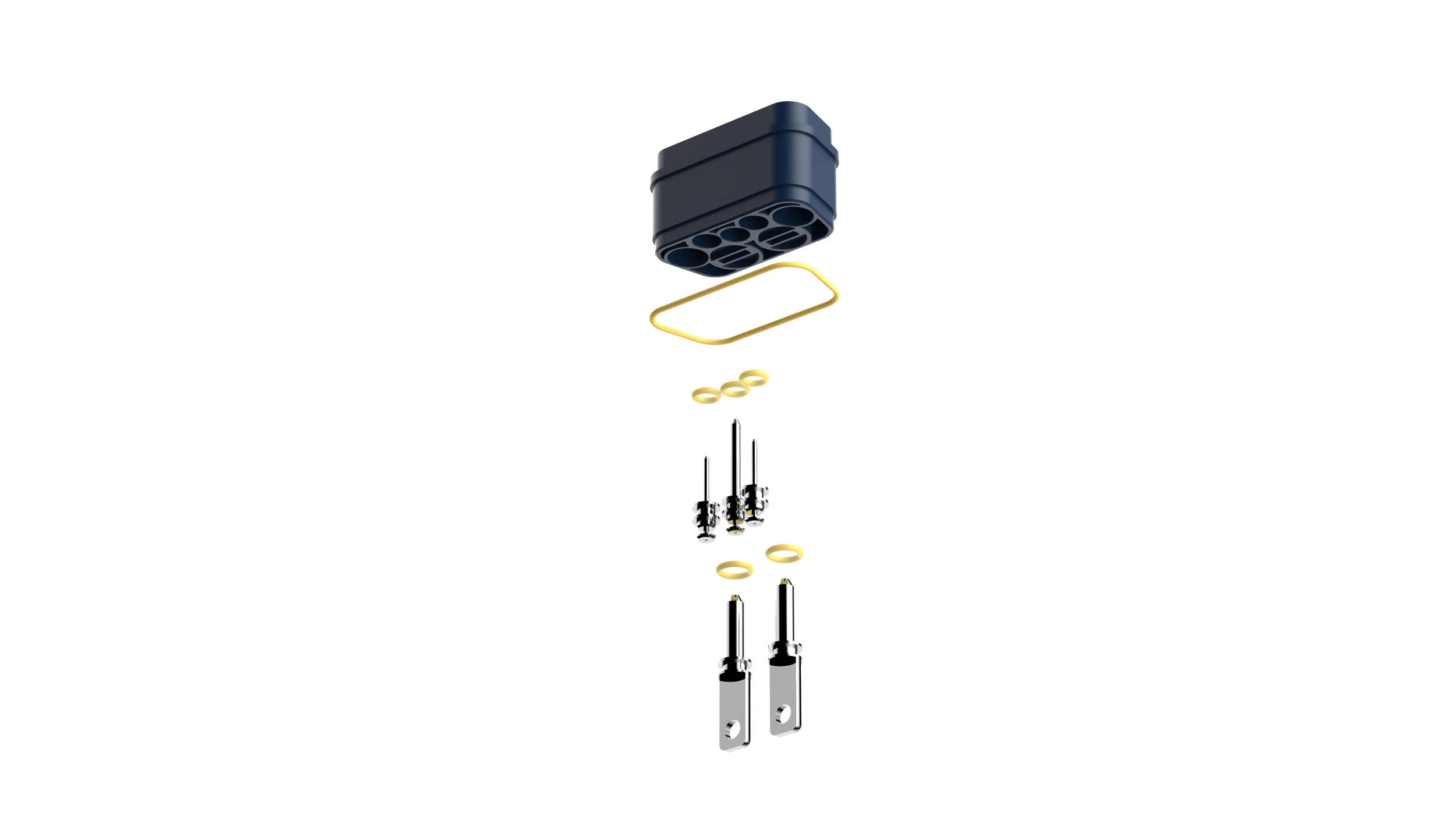

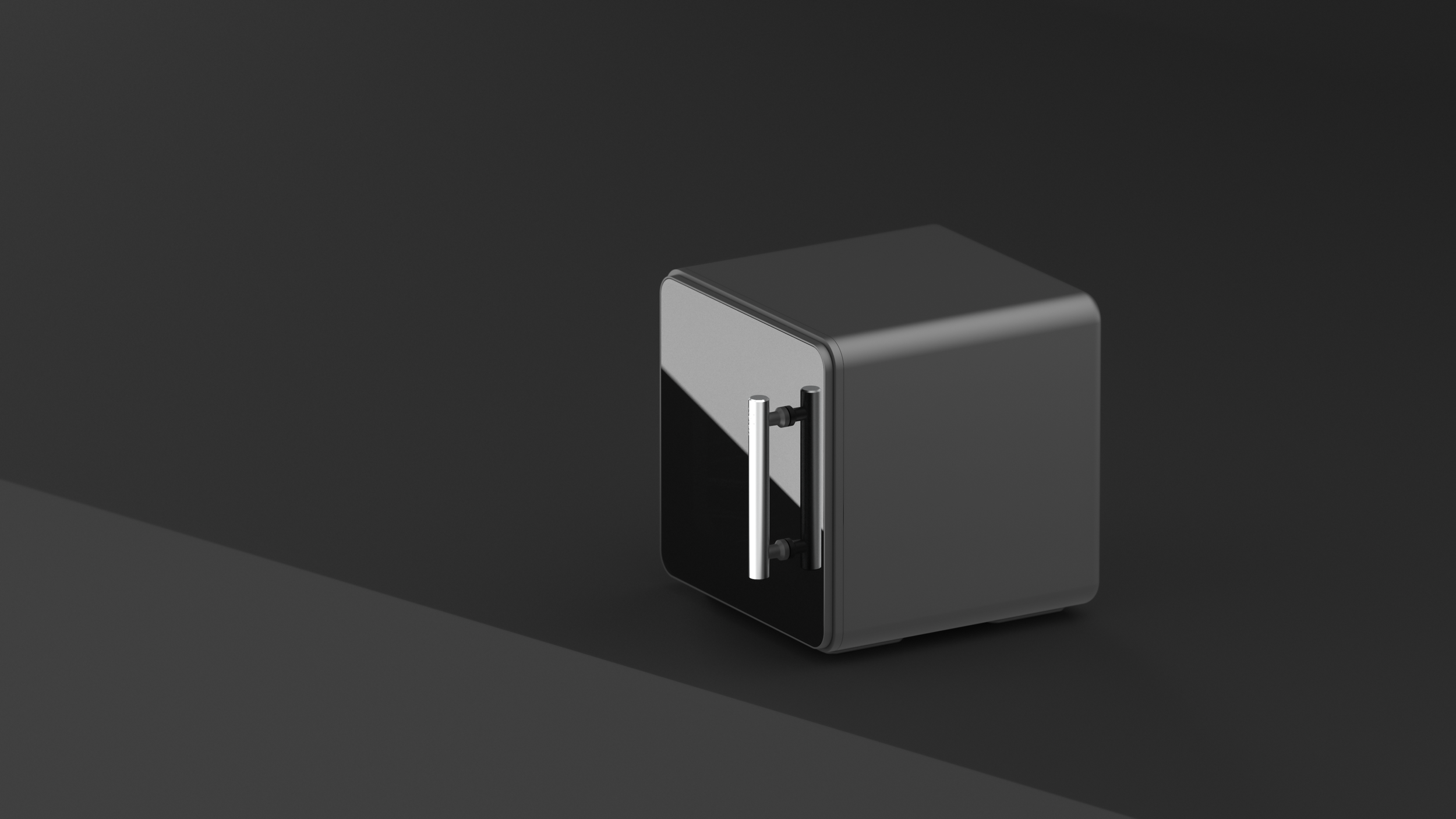

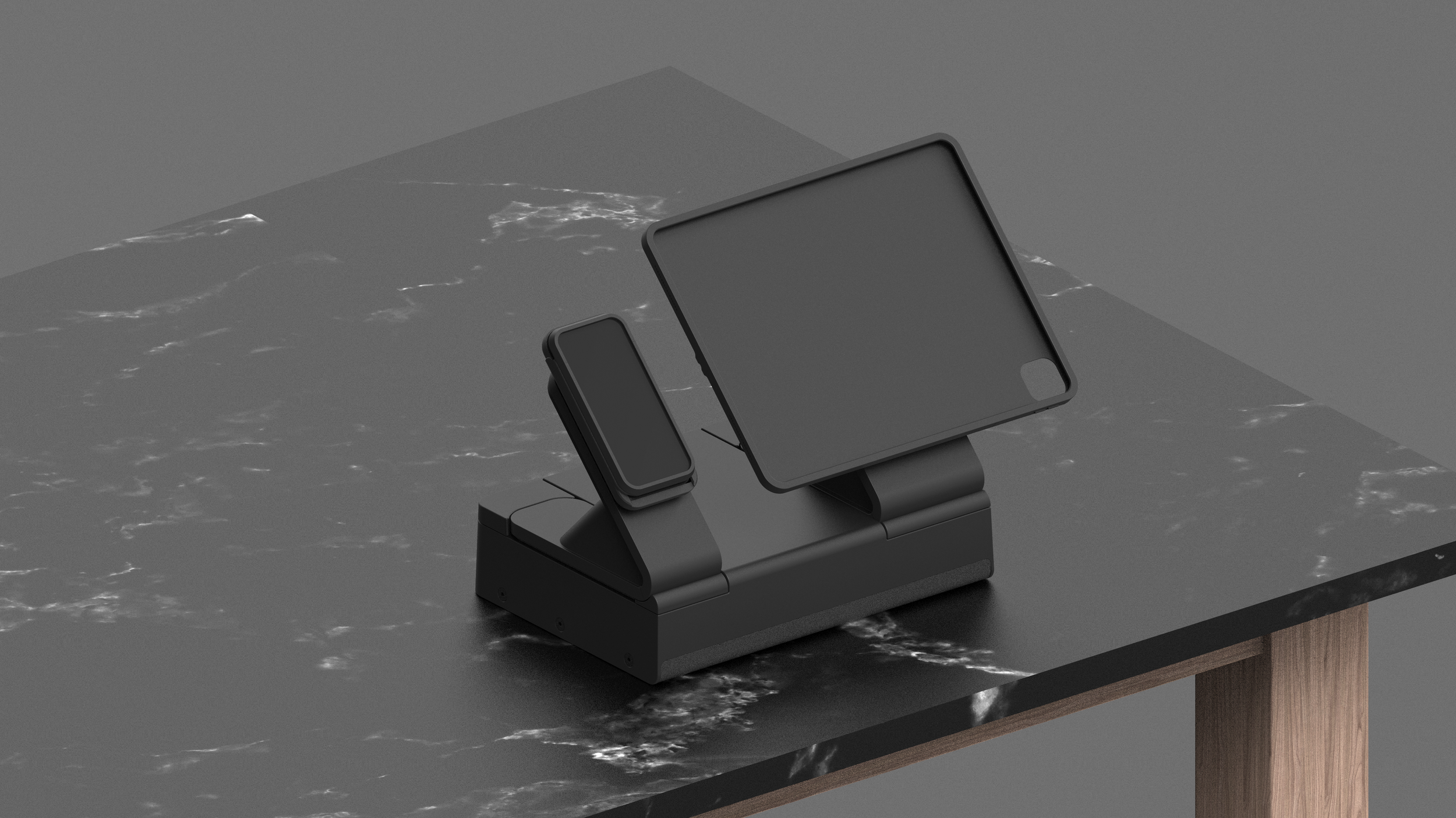

Pilot Builds

Low volume production

Pre production pilot builds are an essential phase in the product development lifecycle, serving as a bridge between prototype validation and full-scale manufacturing. These builds allow engineers and designers to test the manufacturing processes, validate assembly workflows, and identify potential defects or inefficiencies in a controlled environment. By producing a limited quantity of the product, teams can gather critical feedback on component fit, function, and performance, ensuring that any necessary design adjustments or process improvements are made before committing to mass production. This stage ultimately helps reduce costs, mitigate risks, and improve overall product quality and reliability.

Patent Portfolio

-

US20140268518A1 Durable protective battery case

-

US12042140B2 Retention suture assembly

This invention relates to devices that join a pair of edges

This invention relates to devices designed to join a pair of edges securely and efficiently. Such devices are engineered to provide a stable connection between two separate surfaces, often used in manufacturing, construction, and product assembly. The primary focus is on ensuring structural integrity, ease of installation, and durability under various operational conditions. By improving the method of joining edges, this invention aims to enhance the overall performance and longevity of assembled components.

-

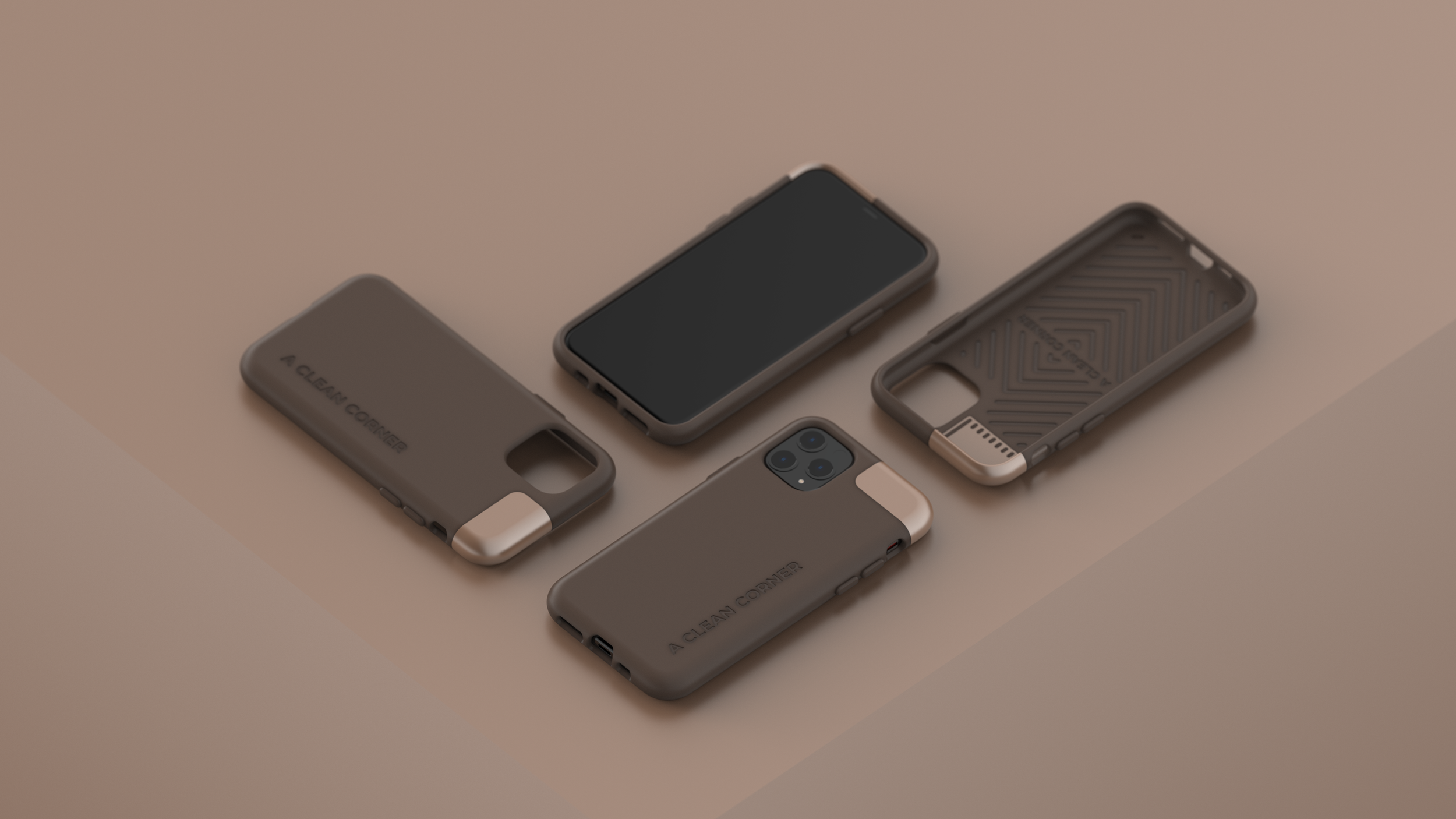

US10277266B1 Mobile device case and methods

A mobile device protective case with an integrated battery combines physical protection and extended power supply into a single accessory. Designed to shield devices from drops, scratches, and everyday wear, these cases also house a rechargeable battery that provides additional runtime for smartphones or tablets. The built-in battery typically connects via the device’s charging port and can be recharged independently, enabling users to maintain device functionality without needing separate power banks or cables. Ideal for users who require prolonged use of their mobile devices in the field or on the go, these cases enhance convenience while preserving device safety.

-

US20230003047A1 Umbrella stand adaptable for support on a table

-

US20190189093A1 Dampening device for an instrumental drum

-

USD727883S1 Mobile phone case

-

USD723530S1 Unbanded battery case for a mobile device

Mophie Juice Pack - Design patent

The Mophie Juice Pack design patent protects the distinctive aesthetic and functional aspects of its portable charging case, which integrates a battery pack seamlessly with a smartphone case. This design patent ensures that the unique contours, form factor, and ergonomic features that differentiate the Mophie Juice Pack from other charging solutions are legally safeguarded. By securing design patent protection, Mophie reinforces its brand identity and prevents competitors from copying the visual design elements that contribute to the product's user-friendly experience and market appeal.

-

USD718293S1 snap battery case for a mobile device

-

USD712389S1 Open-backed mobile device case

-

USD742644S1 Mobile device camera case

-

USD699947S1 Dry mobile device camera case

-

USD980794S1 Charging station